After over 45+ years of industrial service!

- info@triplemindia.com

- (033)26673571

Hot and Cold-friction saw blades are used for cutting : Sections ( Angle, Channel, Beam, Round ) Pipes, Square billets ,Plates Tubes.

Material Cut : Mild Steel, Stainless Steel, Alloy steel , Tool Steel with a temperature in excess of 750° C. When sawing metals below a temperature of 400° C, Cold friction saw blades are used.

The friction heat in the material produces high temperatures which bring the material in a soft plastic condition. In order to clear slags from the tooth gullet a heavy flow(2-3 bar) of water is essential for efficient cutting. A simultaneous slow flow of water (near 1 bar) equal from either side of the Saw is required for body cooling of the Saw. The tooth geometry and tooth pitch are determined by the section and the material to be cut and the design of sawing machine.

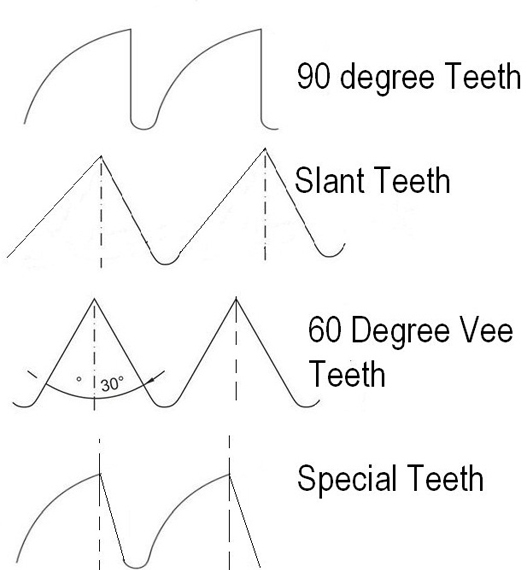

We procure any Kind of tooth according to cutting needs of customer. Most common is 60 Degree Vee-tooth. Slant tooth are required for low Rpm machines and when burr generation is a problem. Special tooth are used according to customers need and Machine requirements. A standard tooth list is shown in following table. Any kind of Special Tooth can be procured as per clients need.

Special Land (flat or slant) on tooth top is given (20% of Pitch) for hot and cold saw for producing extra heat.

Special Land (flat or slant) on tooth top is given (20% of Pitch) for hot and cold saw for producing extra heat.

Low Carbon HSLA steel With Chromium,Vanadium,Niobium imparting regenerative hardness property.

Normally the saw body is Flat ground. For Reducing sound and Vibration Saw body is suitably hollow ground or taper ground according to needs of clients. According to modern rules of safety saw operational sound should be below 100 db.

© 2019 Triplem Engineering Private Limited. | All Rights Reserved .